15 FAH-1 H-100

FACILITIES MAINTENANCE operations

OPERATING PROCEDURES AND OTHER REQUIREMENTS FOR MAINTAINING DEPARTMENT OF STATE FACILITIES ABROAD

(CT:FM-9; 04-28-2025)

(Office of Origin: OBO/OPS/FAC)

15 FAH-1 H-111 HANDBOOK OVERVIEW

(CT:FM-1; 12-29-2005)

15 FAH-1 H-111.1 Scope and Contents

(CT:FM-7; 06-07-2024)

a. The Bureau of Overseas Buildings Operations (OBO) 15 FAH-1, Facilities Maintenance Handbook, provides first-time and experienced maintenance managers with guidance on maintaining post real property facilities. It includes and builds upon technical skills and provides information in setting up and managing a good maintenance program.

b. This handbook outlines procedures for a standard maintenance management system to optimize maintenance resources at Department of State post facilities. The recommended practices, procedures, and forms promote efficient and effective inspections, maintenance, and operations. The handbook includes samples, also, of properly completed requests and reports, preventive maintenance inventory checklists, and facility condition/annual inspection survey formats.

c. One of the requirements for a successful, ongoing maintenance program is the Annual Inspection Summary (AIS) Report, along with the Annual Facility Condition Survey (AFCS), as outlined in this handbook.

d. Posts without the technical expertise to accomplish an annual inspection should contact the Office of Facilities Management in the Directorate of Operations (OBO/OPS/FAC) for assistance. It has a program to assist/train post personnel in conducting formal, detailed inspections on a 1-year cycle. Posts can then use this report as the basis for their AIS reports.

e. The information in this handbook provides some of the basic property–management approaches that have evolved in private industry and Federal agencies. Maintenance personnel should ensure uniform, economical, and effective expenditure of maintenance funds by using these procedures.

f. OBO developed this handbook as a workable maintenance management tool for the maintenance manager.

g. This handbook was also developed as a stand-alone guide for maintenance.

15 FAH-1 H-111.2 Handbook Objectives

(CT:FM-1; 12-29-2005)

This handbook’s objectives:

(1) Provide reference material for maintenance and repair activities;

(2) Standardize maintenance procedures for all posts;

(3) Establish criteria for all maintenance activities; and

(4) Promote a cost-effective maintenance and preventive maintenance program.

15 FAH-1 H-112 FACILITY MANAGER, MEET YOUR POST

(CT:FM-1; 12-29-2005)

15 FAH-1 H-112.1 Get Acquainted with Your Post as Quickly as Possible

(CT:FM-1; 12-29-2005)

15 FAH-1 H-112.1-1 Why?

(CT:FM-3; 06-05-2014)

a. The facility manager’s responsibilities include maintenance and repair of U.S. Government-owned (GO)/operating lease (OL) facilities and related buildings systems.

b. Each post is unique.

15 FAH-1 H-112.1-2 How To Begin

(CT:FM-3; 06-05-2014)

a. Meet the maintenance staff.

b. Meet and get to know other key personnel at post to include the management officer, finance officer, human resources (HR) officer, and general services officer (GSO).

c. Make a general inspection tour (GIT) of post facilities.

d. During the GIT, look for obvious problems.

e. Look at the entire complex .

f. Make courtesy calls on all agency heads and section heads at post as soon as possible after arriving there and leave business cards (issued prior to arriving at post), as appropriate.

g. Seek a key role, if not already established, on various post boards and committees (e.g., housing board, safety committee) on which facility maintenance manager expertise would be highly beneficial.

h. Repeat facility inspections every 6 months during your tour.

15 FAH-1 H-112.1-3 Don’t Go Alone!

(CT:FM-2; 03-01-2011)

a. Take the locally employed staff (LE staff) maintenance supervisor or senior shop supervisors on a tour of the facilities; these personnel can provide valuable information.

b. Request their ideas on the goals of the maintenance program, what they believe is working well, and what needs improving from the senior supervisors.

c. The tour should result in an appreciation of:

(1) Size and mission of the post;

(2) Current conditions of the facilities;

(3) Areas requiring immediate attention;

(4) Areas requiring future investigation; and

(5) Areas that lack adequate management information.

15 FAH-1 H-112.2 Develop a Facility Notebook

(CT:FM-1; 12-29-2005)

15 FAH-1 H-112.2-1 What Is a Facility Notebook?

(CT:FM-1; 12-29-2005)

A facility notebook is:

(1) A single source of summarized historical maintenance information;

(2) A basis of continuity during turnovers of post general services officers, facility managers, and facility supervisors; and

(3) A tool for maintenance management of post facilities.

15 FAH-1 H-112.2-2 What Does the Facility Notebook Contain?

(CT:FM-7; 06-07-2024)

a. The facility notebook should contain the following list of assets:

(1) Assets owned or under operating lease (OL) by the U.S. Government;

(2) Basic facility planning information;

(3) Preventive maintenance inventory/checklist;

(4) Control inspection inventory/checklist;

(5) Requirements (what needs to be done?);

(6) Current Annual Inspection Summary (AIS);

(7) Latest fire inspection report;

(8) Most recent control inspection reports;

(9) Resource request log;

(10) Resources (what is available to work with?);

(11) Current routine maintenance and repair (M&R) and Diplomatic and Program (DP) budget;

(12) Plans and actions (what is planned to be done and what has been done in the past?);

(13) Scheduled maintenance service contract log;

(14) Maintenance record log;

(15) Summary of post maintenance policies and directives;

(16) List of critical items of maintenance and repair;

(17) Facility maintenance notes from previous managers;

(18) Copy of utility contract(s);

(19) History of energy consumption; and

(20) Appointment and authorization letters for the contracting officer’s representative (COR) for facility support contracts and contract authority.

b. Each maintenance manager should update and or develop the facilities notebook while assigned to the post. If there is no facility notebook at post, make one yourself, using the general guidelines above!

15 FAH-1 H-112.3 Determining Maintenance Requirements

(CT:FM-5; 06-13-2019)

a. To set up a good maintenance program, the first step is to know precisely what needs to be maintained. Without an equipment and facility inventory, a logical plan of action is not possible. The instructions for developing and maintaining this inventory is in the Work Orders for Windows (WOW) User’s Manual located on the Department’s Intranet PASS (Post Administrative Software Suite) homepage.

b. Some of the equipment data will have already been collected and will be available in the form of real property records or within maintenance office files. In other cases, a survey of post facilities will be required.

15 FAH-1 H-113 EVALUATING THE FACILITY MAINTENANCE MANAGEMENT SYSTEM AT POST

(CT:FM-1; 12-29-2005)

15 FAH-1 H-113.1 Facility Maintenance Management System

(CT:FM-1; 12-29-2005)

a. This section is designed to:

(1) Introduce the maintenance manager to various aspects of facility maintenance management; and

(2) Help the maintenance manager evaluate each aspect of the program by asking questions to stimulate thought about the post’s current maintenance management.

b. The rest of the Facilities Maintenance Handbook addresses the various aspects of facilities maintenance management in greater detail:

(1) A work control system for getting work done;

(2) Records keeping;

(3) Annual Inspection Summary Report;

(4) General considerations;

(5) Preventive maintenance; and

(6) Automated maintenance management control systems.

15 FAH-1 H-113.2 A Work Control System for Getting the Work Done

(CT:FM-1; 12-29-2005)

As the nucleus of an effective post facilities management effort, a work control system includes:

(1) Work identification;

(2) Workload planning;

(3) Work accomplishment; and

(4) Work appraisal (quality control).

15 FAH-1 H-113.3 Work Identification

(CT:FM-7; 06-07-2024)

a. Maintenance managers identify work and manage any work that the Office of Area Management in the Directorate of Operations (OBO/OPS/AM) has approved for in-house accomplishment.

b. The maintenance manager should identify what needs to be done at the post before problems become critical.

c. Early identification will allow time for material procurement, job planning, and efficient work scheduling.

d. There are three major ways of identifying work:

(1) Inspections;

(2) Staff observation; and

(3) Work orders.

15 FAH-1 H-113.4 Inspections

(CT:FM-1; 12-29-2005)

The primary inspection programs at the post are:

(1) Maintenance management inspections;

(2) Annual facility condition survey;

(3) Preventive maintenance (PM) program; and

(4) Specialized inspection program; e.g., elevators.

15 FAH-1 H-113.5 Maintenance Management Inspections

(CT:FM-3; 06-05-2014)

a. The maintenance manager should conduct a complete general inspection of post upon arrival and then every 6 months.

b. Identifying facility deficiencies on a routine basis facilitates planning and scheduling of needed repairs.

15 FAH-1 H-113.6 Annual Facility Condition Survey

(CT:FM-7; 06-07-2024)

a. Each year, technically qualified maintenance personnel conduct annual facility condition surveys (AFCS).

b. The surveys are designed specifically to look for:

(1) Structural deficiencies;

(2) Electrical deficiencies; and

(3) Mechanical deficiencies.

c. Annual facility condition surveys are due to the Facility Management Administrative Division (FMA) in the Office of Facility Management (OBO/OPS/FAC/FMA) by September 30 each year.

15 FAH-1 H-113.7 Facility Condition Inspection Objective

(CT:FM-1; 12-29-2005)

a. The objective is to identify major deficiencies early when timely repairs will be much less costly.

b. For guidance on developing a facility condition inspection program, see 15 FAH-1 H-116.

15 FAH-1 H-113.8 Preventive Maintenance (PM) Program

(CT:FM-1; 12-29-2005)

a. Preventive maintenance is the planned periodic inspection and servicing of equipment by maintenance personnel.

b. The main objective of preventive maintenance is to reduce the probability of equipment breakdown and resulting high downtime costs.

c. Periodic servicing of equipment lengthens equipment life and reduces breakdown by:

(1) Identifying present and potential needed repairs;

(2) Accomplishing minor maintenance during inspection; and

(3) Scheduling the repairs for future maintenance attention.

15 FAH-1 H-113.9 Specialized Inspections Program

(CT:FM-1; 12-29-2005)

a. Certain facilities and equipment, especially those involving safety, require periodic inspection and certification. Usually, certifications are accomplished by OBO or by contract. Post records and appropriate OBO personnel can offer information on which items need these inspections.

b. Identify and note each specialized inspection or certification.

c. Coordinate with OBO to complete these inspections and certifications before they expire.

d. Determine if annual equipment certificates are being completed.

15 FAH-1 H-113.10 Work Identification Sources

(CT:FM-1; 12-29-2005)

In addition to inspection programs, other sources of work identification must be considered.

15 FAH-1 H-113.10-1 Reports from In-House Staff

(CT:FM-1; 12-29-2005)

Establish a single point of contact for in-house staff to report observed facilities deficiencies, and remind all staff that reporting such deficiencies is their responsibility.

15 FAH-1 H-113.10-2 Work Identified by Customers through Service Calls

(CT:FM-1; 12-29-2005)

Service calls will consist only of emergency work, or minor but necessary work, which failure to perform could result in:

(1) Loss of life;

(2) Impairment of safety;

(3) Loss of or damage to U.S. Government property;

(4) Environmental pollution; and/or

(5) Failure of a vital mission objective.

15 FAH-1 H-113.10-3 Work Identified by Customers Through Written Work Orders

(CT:FM-1; 12-29-2005)

a. Written work orders are made by customers for unscheduled work, which is work that occurs on a one-time basis.

b. A work-order log for this work should be maintained.

15 FAH-1 H-113.11 Workload Planning

(CT:FM-1; 12-29-2005)

a. Workload planning is used to determine:

(1) What is the work to be accomplished?

(2) How is the work to be accomplished? and

(3) When is the work to be accomplished?

b. Establishing work plans and schedules will help in decision making.

15 FAH-1 H-113.12 In-House Work Accomplishment and Contracting Capability

(CT:FM-1; 12-29-2005)

a. A work control system provides the manager with the necessary resources to accomplish the work.

b. It is the maintenance manager’s responsibility to ensure that the work gets completed properly and within budget.

c. Work appraisal determines if the work was done as planned and feeds that information back into the other work control system elements. The maintenance manager should perform work appraisal on:

(1) Scheduled work;

(2) Unscheduled work; and

(3) The work force.

d. Contracting capability:

(1) May be used for minor construction and alterations;

(2) Provides post with an excellent method for reducing work backlog;

(3) Provides access to special capabilities or skills that may not be available at post; and

(4) Allows the manager to concentrate on urgent or critical maintenance and repair rather than on routine services.

15 FAH-1 H-113.13 Facility Recordkeeping

(CT:FM-1; 12-29-2005)

Accurate records should yield excellent returns when compared to the time required to update and maintain the records.

15 FAH-1 H-113.14 Reporting

(CT:FM-1; 12-29-2005)

Reports submitted by post reflect the quality of the facilities management program. Major reports include:

(1) Budgetary reports for post budget and finance officer; and

(2) Annual inspection summary (AIS).

15 FAH-1 H-113.15 General Considerations

(CT:FM-1; 12-29-2005)

Additional areas of responsibility should also be evaluated. These include:

(1) Fire and life safety;

(2) Accessibility considerations;

(3) Energy management;

(4) Safety considerations;

(5) Environmental control and abatement; and

(6) Security considerations.

15 FAH-1 H-113.16 Developing Long-Range Facility Management Goals

(CT:FM-3; 06-05-2014)

a. After evaluating the facilities maintenance management system, the maintenance manager should be in a position to personally establish long-range goals and major milestones.

b. Long-range goals make day-to-day operations more effective.

c. Attention should be focused on seven areas of maintenance management:

(1) Work identification, prioritization, and funding (to include cost estimates for the planned maintenance);

(2) Work-order system for getting the work done;

(3) Contracting;

(4) Record keeping;

(5) Reporting;

(6) Specialized inspections and certifications; and

(7) General considerations.

d. Planned actions should be recorded on a facility maintenance timetable. The timetable provides the maintenance manager with a long-range (2-year) schedule of significant maintenance events. After completing the evaluation of the facility maintenance management system, action should be taken to improve any weak areas. The timetable can be used to plan and schedule the work required to correct any weaknesses.

15 FAH-1 H-114 A WORK-ORDER SYSTEM FOR GETTING THE WORK DONE

(CT:FM-1; 12-29-2005)

15 FAH-1 H-114.1 Work-Order System and Controls

(CT:FM-7; 06-07-2024)

a. A basic requirement of good maintenance management is communication between those who need something done, those who supervise and direct what will be done, and those who do the actual work. A good work-order system not only provides management information but also:

(1) Improves communication of exactly what needs to be done;

(2) Documents serious or recurring maintenance problems for historical purposes;

(3) Provides the means to control expenditures of labor and material resources; and

(4) Provides the maintenance section with a properly filled out work order with all the information needed to perform the requested work.

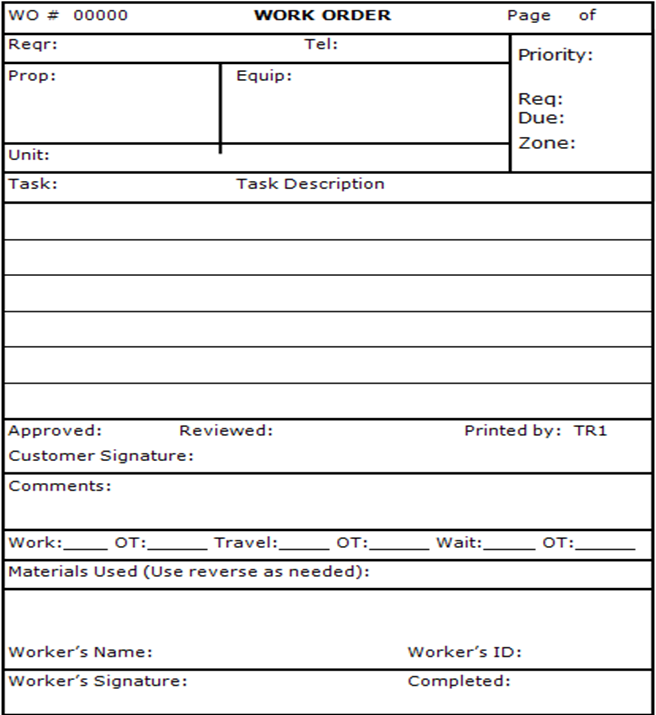

b. When work originates from within the maintenance section, as a result of preventive maintenance or annual facility condition surveys, somewhat less emphasis can be placed on the “When,” “Why,” and “Who” blocks, but use the format for work orders and material requisitioning shown in 15 FAH-1 Exhibit H-114.1, Work-Order Format.

c. The Work Orders for Windows (WOW), is the Department standard for assisting personnel in facility maintenance management. Posts should refer to the user’s manual located on the Department’s Intranet PASS (Post Administrative Software Suite) homepage. Contact the Facilities Management Administration Division in the Office of Facility Management (OBO/OPS/FAC/FMA) if the program has not been installed at post.

15 FAH-1 H-114.2 Identify the Work

(CT:FM-7; 06-07-2024)

a. Emergencies: Phoned in by customers.

b. Formal work orders: Written orders by post customers to have facilities maintenance and repair work accomplished.

c. AFCS: A written report by qualified inspectors that identifies facilities and equipment that require maintenance and repair activities.

d. Scheduled work: Jobs that must be done repetitively, such as grounds maintenance, preventive maintenance, and attending to the boiler.

15 FAH-1 H-114.3 Develop Work Orders

(CT:FM-1; 12-29-2005)

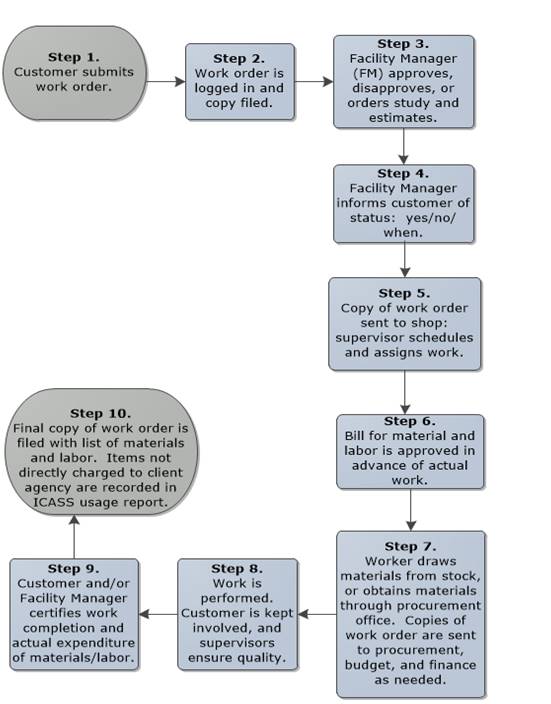

A “road map” showing the process and the functions to be performed at each stop is shown as a work-order flow chart in 15 FAH-1 Exhibit H-114.3. Obviously, the route and steps necessary to process a work order will vary from post to post, depending on the size and organization of the maintenance section; however, within reason, the functions should be done regardless of post size.

15 FAH-1 H-114.4 Initial Maintenance Manager Review

(CT:FM-1; 12-29-2005)

a. The maintenance manager should initially review the work order to assess its validity and to assign it a work priority. The priority is a numerical ranking assigned to all work. It is based on a pre-established set of criteria. Below are the recommended priorities:

(1) Priority 1—Life, safety, security, and other work, which, if not done immediately, would endanger post personnel and/or property;

(2) Priority 2—Other life, safety, and security work needed, but not urgently;

(3) Priority 3—Work required within a short period of time;

(4) Priority 4—Work required ahead of routine work; and

(5) Priority 5—Routine maintenance and repair work.

b. These priorities should be used throughout the life of the work-order process to generally determine the order in which they should be processed, receive post resources (materials and labor hours), and be completed.

c. The absence or misuse (e.g., inflation) of a priority system results in all work being treated equally and increases the chance that limited resources will not be available for truly important work.

d. When the requestor has asked for work that is against policy, return the request with an explanatory comment. In times of limited resources, as might occur midway through a fiscal year, valid but low-priority projects should be placed on the “back burner” for future accomplishment. Advise the customer accordingly.

15 FAH-1 H-114.5 Make Work Logs

(CT:FM-3; 06-05-2014)

a. A work control system needs a tracking system for the work that has been identified. Maintaining logs that record the different types of work identified is a simple way of staying on top of what needs to be done. The Work Orders for Windows (WOW) program provides a work log tracking system.

b. Work log:

(1) Enter both scheduled and unscheduled work into the WOW system;

(2) Unscheduled work is identified through customer work requests and the Annual Facility Condition Survey; and

(3) A byproduct of the preventive maintenance program is the identification of equipment defects. Report these defects to the work-order clerk to prepare work orders.

15 FAH-1 H-114.6 Determine Methods of Accomplishment

(CT:FM-7; 06-07-2024)

Determine which of the following (or combination thereof) will actually do the work:

(1) Post maintenance personnel;

(2) Local contracting; or

(3) OBO-provided resources.

15 FAH-1 H-114.6-1 Submit Project Funding Requests

(CT:FM-7; 06-07-2024)

a. Project funding requests provide a method of presenting special maintenance and repair (M&R) and minor improvement projects to OBO for funding consideration.

b. Submit project funding requests in accordance with OBO requirements.

15 FAH-1 H-114.6-2 Work Identified on a Routine Basis

(CT:FM-7; 06-07-2024)

Submit project funding requests to OBO throughout the year as new requirements are identified. Do not wait for the Annual Inspection Summary (AIS) Report to submit project funding requests.

15 FAH-1 H-114.6-3 Emergency Work

(CT:FM-7; 06-07-2024)

Report to OBO by phone with a follow-up email if post does not have enough resources to accomplish necessary emergency work.

15 FAH-1 H-114.6-4 Estimate the Value of a Job

(CT:FM-1; 12-29-2005)

To estimate the value of a job:

(1) Obtain estimates for materials costs from material suppliers. Provide a rough estimate of the labor costs; and

(2) Call local contractors for quotations.

15 FAH-1 H-114.7 Plan the Workload

(CT:FM-1; 12-29-2005)

a. Workload planning determines when the work is to be accomplished.

b. The work plan comes from the scheduled, unscheduled, and backlog of work that is recorded.

c. Maintenance backlog is the name for all valid work that is not scheduled for accomplishment.

d. Work selected from the backlog for inclusion on the work plan is chosen on the basis of its priority.

15 FAH-1 H-114.8 Do the Work

(CT:FM-1; 12-29-2005)

a. The maintenance manager sees that planned work gets done.

b. The work-order system has provided the supervisor with the required resources to do specific tasks, at specific locations, in specific time frames.

c. Work appraisal determines whether the work was done as planned and feeds back information into the other system files.

d. Residents should be notified prior to work being started and an evaluation card should be left with the resident to provide comments on completed work for return to the facility manager.

15 FAH-1 H-114.9 Develop Facility History Files

(CT:FM-1; 12-29-2005)

a. Facility history files should be developed and maintained regularly. These files contain data on completed work done for each facility at post.

b. Use these files to:

(1) Identify trends in maintenance and repair problems;

(2) Plan for scheduled work;

(3) Review maintenance and repair history;

(4) Identify emergency or specialized equipment located in each facility;

(5) Determine the condition of each facility; and/or

(6) Determine date of last significant repair, alteration, roof replacement, and other major maintenance work.

15 FAH-1 H-114.10 Obtain Budget Feedback

(CT:FM-1; 12-29-2005)

Information on the logs and plans permits easy development of budget requirements based on clearly documented facts and figures about work accomplished. It also identifies backlog of unfunded requirements.

15 FAH-1 H-114.11 Tell Post about the System

(CT:FM-1; 12-29-2005)

a. Develop and give a clear, simple presentation of the work-order system.

b. Write a post administrative notice so that customers can easily interface with the work-order system.

15 FAH-1 H-115 RECORDKEEPING

(CT:FM-1; 12-29-2005)

15 FAH-1 H-115.1 Recordkeeping Is Important to Good Maintenance Management

(CT:FM-1; 12-29-2005)

a. Written records provide a basis for the maintenance manager to manage work flow, plan, and budget.

b. Records kept at post are used to track maintenance and repair history and support budget submissions.

15 FAH-1 H-115.2 Plans and Actions

(CT:FM-1; 12-29-2005)

a. Post plans and actions are summaries of what has been done and what is going to be done. The maintenance manager needs this information handy to answer questions about work status, make decisions about future work, and study past trends.

b. Maintenance managers play an important role in the delivery of International Cooperative Administrative Support Services (ICASS) services to the various entities at posts. Knowledge of ICASS through attendance at the general services officer (GSO) course and through actual contact with ICASS and its processes is essential in being an effective maintenance manager.

c. The facilities manager (FM) should attend the local ICASS council meetings at post to gain a better understanding of the organization and its established priorities.

15 FAH-1 H-115.2-1 Management’s Facility Notes

(CT:FM-1; 12-29-2005)

a. Note items that management has expressed particular interest in having accomplished.

b. Note personal observations about facilities maintenance and management that may prove helpful in the future.

c. Look in the post files for previous administrative notices issued.

d. Retain copy of current post facilities budget in facility notes.

15 FAH-1 H-115.2-2 Instructions for Ordering Materials and Supplies

(CT:FM-1; 12-29-2005)

a. The facilities manager (FM) must approve all materials ordered.

b. Materials and supplies must be procured to accomplish maintenance tasks. A balance must be maintained between:

(1) Need to expedite the work;

(2) Need for accountability;

(3) Need to procure or fabricate; and

(4) Need to stock or buy local purchase (impacts petty cash control) items.

15 FAH-1 H-115.3 Developing Post Facility Files

(CT:FM-1; 12-29-2005)

a. Facility files are an important maintenance management tool and must be kept up to date.

b. Do not include classified or controlled documents in the files.

15 FAH-1 H-115.4 What Files to Keep?

(CT:FM-1; 12-29-2005)

Keep the following files:

(1) Annual work orders;

(2) Annual completed work orders;

(3) Annual contracts; and

(4) Facility histories.

15 FAH-1 H-115.5 Developing an Annual Work Plan

(CT:FM-3; 06-05-2014)

Numerous benefits derive from establishing annual work plans:

(1) Improved facility condition;

(2) Increased work force productivity;

(3) Enhanced work planning and scheduling;

(4) Improved resource management;

(5) Better support of mission and personnel; and

(6) More orderly contracting and material acquisition.

15 FAH-1 H-115.5-1 Annual In-House Work Plans

(CT:FM-3; 06-05-2014)

a. Any minor or urgent work should be extracted and assigned work orders for early accomplishment. Likewise, work intended for a future year should be filed for review during the next Annual Facilities Condition Survey.

b. Sort remaining in-house work by craft, and enter it on the annual work plan format shown in 15 FAH-1 Exhibit H-115.5-1(1), In-House Work-Plan Format, in building number order.

c. Convert the rough-scope description on each write-up to an estimate of labor hours and materials required.

d. The remaining work can then be scheduled as fill-in workloads up to the total hours available in each month. One school of thought in work scheduling is to overload the first month by about 15 percent, so that if for any reason some work must be deferred (nonreceipt of materials, changing requirements, etc.), other work orders will be ready to take up the slack. If all goes as planned, the overload then shifts to the following month as a bow-wave effect.

e. In addition to deficiencies discovered during the Annual Facilities Condition Survey, other work can be added during the year as work orders are received, or as other preventive maintenance inspections identify maintenance and repair projects. Likewise, events that require support by maintenance workers, such as the annual Independence Day celebration, should be included in the work plan with labor hours reserved for that support.

f. Estimate the hours available in each month. Estimates should consider holidays, vacation periods, sick leave, and other factors. See 15 FAH-1 Exhibit H-115.5-1(2), Estimating Available Hours.

g. In scheduling each work item for a particular month, schedule seasonally independent items first. Keep a running total of labor hours for each month during monthly work scheduling so that hours stay within the hours available.

h. Depending on the source of supply and normal delivery lead-time, the in-house work plan schedule should also be used to schedule detailed work planning and material ordering during the year.

15 FAH-1 H-115.5-2 Annual Contract Work Plans

(CT:FM-7; 06-07-2024)

a. The contract work plan is used to manage and track the key events leading to the eventual completion of contract project work.

b. This plan covers special maintenance and repair (M&R) projects. These requirements are generally identified during the Annual Facilities Condition Survey but could also result from tenant/occupant work orders. Justifications for considering an outside contractor include that the work may be hazardous, may require extraordinary skill, may require specialized equipment that cannot be rented, or the existing work force is too small to handle the workload.

c. The post regional security officer and OBO must coordinate with the post on these projects. An annual contract work-plan format is shown in 15 FAH-1 Exhibit H-115.5-2.

15 FAH-1 H-116 ANNUAL FACILITY CONDITION SURVEY AND ANNUAL INSPECTION SUMMARY REPORT (AIS)

(CT:FM-1; 12-29-2005)

15 FAH-1 H-116.1 Annual Facility Condition Survey Program

(CT:FM-7; 06-07-2024)

a. The Annual Facility Condition Survey (AFCS) is an annual assessment of facilities conditions by technically qualified maintenance personnel.

b. Inspectors look for:

(1) Structural deficiencies;

(2) Electrical deficiencies; and

(3) Mechanical deficiencies.

c. All U.S. Government-owned and operating lease (OL) facilities should be surveyed in detail annually. Where deficiencies exist, complete a facility condition survey deficiency format for each project. A facility condition deficiency survey format is shown in 15 FAH-1 Exhibit H-116.1.

15 FAH-1 H-116.2 Facility Condition Deficiencies

(CT:FM-1; 12-29-2005)

Facility condition deficiencies are problems found in the property that require:

· Maintenance

· Repair

· Replacement

15 FAH-1 H-116.3 Annual Inspection Summary (AIS)

(CT:FM-7; 06-07-2024)

a. The annual inspection summary (AIS) is a summary of deficiencies taken from the annual facility condition survey deficiency formats. An AIS example is given as 15 FAH-1 Exhibit H-116.3.

b. Only maintenance and repair work can be shown on the AIS.

c. The AIS acts as a maintenance management tool for:

(1) Justifying funds for unfunded facility condition survey deficiencies;

(2) Developing long-term facilities maintenance objectives;

(3) Developing repair/maintenance work plans; and

(4) Documenting the maintenance backlog for the post.

d. OBO requires the AIS and its inclusion in the budget submission.

e. The post maintenance supervisor or designated representative completes the AIS.

f. Do not report items of less than $1,000.

g. Individual small items of less than $1,000 may be combined to reach the minimum amount if these small items are for the same facility and the same type deficiency. Also, individual, same-type deficiency projects in the same facility may be combined into one project, as long as the total cost exceeds $1,000.

15 FAH-1 H-117 GENERAL CONSIDERATIONS

(CT:FM-1; 12-29-2005)

In addition to the daily maintenance management considerations discussed so far, there are six other general considerations that are vitally important:

(1) Fire and life safety;

(2) Americans with Disabilities Act of 1990 (ADA) accessibility;

(3) Energy management;

(4) Safety considerations;

(5) Environmental control and abatement; and

(6) Security considerations.

15 FAH-1 H-117.1 Fire and Life Safety Considerations

(CT:FM-7; 06-07-2024)

The FM may be responsible for a continuous fire prevention program. See the Fire Protection Guide produced OBO for establishing a program.

15 FAH-1 H-117.2 Accessibility Considerations

(CT:FM-7; 06-07-2024)

The FM, when undertaking a major facilities renovation, should coordinate with OBO to ensure that applicable accessibility standards are met. Such standards apply under the Architectural Barriers Act and the Rehabilitation Act.

15 FAH-1 H-117.3 Energy Management Considerations

(CT:FM-9; 04-28-2025)

The FM may be responsible for energy management at the post, including being knowledgeable on all matters concerning:

(1) Energy conservation and awareness;

(2) Use of alternative energy sources; and

(3) The Bureau of Overseas Buildings Operations (OBO) Utility Optimization (UO) program and utilities cost reduction; contact the Office of Design and Engineering in the Directorate of Project Development, Coordination, and Support (OBO/PDCS/DE) for special requirements.

15 FAH-1 H-117.4 Safety and Health Considerations

(CT:FM-7; 06-07-2024)

Post is required to implement a safety, health, and environmental management program in accordance with 15 FAM 900. The FM may be assigned the collateral duty position of post occupational safety and health officer (POSHO) and be responsible for implementing this program for the deputy principal officer. Assistance in implementing the program is available from the Office of Safety, Health and Environmental Management in the Directorate of Operations (OBO/OPS/SHEM).

15 FAH-1 H-117.5 Environmental Control and Abatement

(CT:FM-7; 06-07-2024)

a. General environmental concerns include:

(1) Managing asbestos;

(2) Ensuring water quality;

(3) Managing chlorofluorocarbons (CFCs); and

(4) Managing underground storage tanks and remote refueling points.

b. Contact the Facility Management and Administration Division in the Office of Facility Management (OBO/OPS/FAC/FMA) to discuss these issues.

15 FAH-1 H-117.6 Security Considerations

(CT:FM-7; 06-07-2024)

Check with the management officer and the regional security officer (RSO) to ascertain security procedures that affect the char force, routine service in restricted areas, and maintenance of security-related equipment. Contact the Office of Security Management in the Directorate of Construction and Security Management (OBO/CSM/SM) concerning security issues pertaining to facility projects.

15 FAH-1 H-118 PREVENTIVE MAINTENANCE (pm)

(CT:FM-1; 12-29-2005)

15 FAH-1 H-118.1 General

(CT:FM-7; 06-07-2024)

a. The benefits of preventive maintenance (PM) to major building systems and equipment are direct and substantial.

b. PM requires:

(1) Post management leadership and commitment;

(2) Compliance and discipline; and

(3) Management understanding of the “true cost of poor maintenance.”

c. Preventive maintenance is proactive.

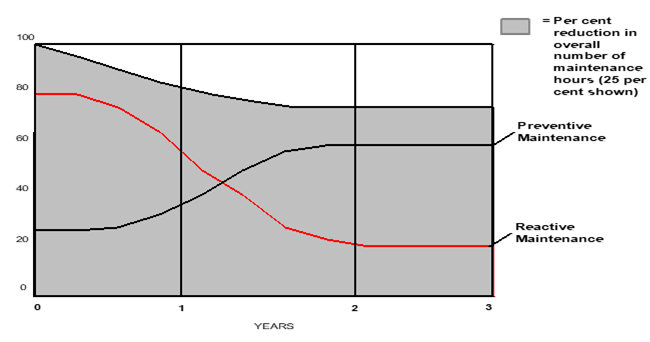

d. As preventive maintenance increases as a proportion of maintenance workload, overall maintenance workload will be reduced (see 15 FAH-1 Exhibit H-118.1).

15 FAH-1 H-118.2 Preventive Maintenance (PM) Elements

(CT:FM-7; 06-07-2024)

A good PM program has several elements:

(1) Operating equipment correctly;

(2) Lubricating with the right quantity, the right kind, in the right place, at the right time;

(3) Predicting wear and deterioration by regularly checking, measuring, and adjusting;

(4) Making routine inspection;

(5) Maintaining adequate levels of parts and consumables (stock or market source);

(6) Preventing failures by replacing parts regularly before they fail; and

(7) Correcting potential failure points when inspections indicate the need.

15 FAH-1 H-118.3 Major Factors to Consider in Building a Preventive Maintenance (PM) Program

(CT:FM-7; 06-07-2024)

Consider the following major factors when building a PM program:

(1) Inventory and identify the equipment;

(2) Prepare standard instructions for all PM work;

(3) Establish frequency of PM activities;

(4) Determine labor, time, and material required;

(5) Create permanent files and records to provide information on PM work performed;

(6) Prepare work orders;

(7) Determine who performs PM work;

(8) Write work orders for repairs identified during PM;

(9) Analyze reports of completed PM work orders to determine high-cost areas;

(10) Adjust frequencies based on experience;

(11) Periodically review equipment on the PM schedule and delete equipment that no longer requires PM; and

(12) Add items, as necessary, to PM program.

15 FAH-1 H-118.4 Where to Apply Preventive Maintenance (PM)

(CT:FM-7; 06-07-2024)

a. As a concept of operations, PM is on the opposite end of the scale from “repair after breakdown.” From an economic viewpoint, operating at either end of this scale will result in needless, wasteful expenditures.

b. Follow these general criteria to approach that midscale balance between PM and breakdown repair at which total maintenance costs are at a minimum:

(1) Do not include any component or piece of equipment that costs less than US$1,000 to replace in the systematic PM program, except as noted in subparagraph b(3) of this section;

(2) Do not include any component or piece of equipment that has a local sales value greater than or equal to 65 percent of its replacement cost; and

(3) Unless a component or piece of equipment has an “unacceptable impact” of failure (safety, security, minimum comfort standards, secondary damage, etc.), economic considerations should govern the frequency of preventive maintenance and servicing.

15 FAH-1 H-119 unassigned

15 FAH-1 Exhibit H-114.1

Work-Order Format

(CT:FM-1; 12-29-2005)

15 FAH-1 Exhibit H-114.2

The Work-Order Cycle

(CT:FM-5; 06-13-2019)