14 FAH-1 H-300

RECEIPT AND STORAGE

RECEIPT AND STORAGE PROCEDURES Worldwide

(CT:PPM-50; 10-16-2024)

(Office of Origin: A/LM)

14 FAH-1 H-311 SCOPE

(CT:PPM-22; 03-03-2016)

(State/USAID)

a. This subchapter 14 FAH-1 H-310 provides the procedures for managing personal property during the receipt functions and while the property is in storage at U.S. Government controlled space worldwide. The heading "State/USAID" applies to USAID at foreign locations only and Department of State worldwide both domestic and foreign. If marked as "State only" it does not apply to USAID and applies to State both domestic and foreign locations. If marked as "Domestic State only" that section applies only to the Department of State operations located in the U.S. and not to foreign locations.

b. During recent attacks on U.S. facilities, intruders used unsecured mission property as improvised weapons, i.e. weapons of opportunity. To ensure the safety of mission personnel and property, employees must properly secure and store all materials that can be used as improvised weapons, including, but not limited to, flammable liquids, paint, hand tools, power tools, rebar, rigid conduit, loose scaffolding, and other loose construction materials or equipment. Such property must be stored as securely as possible when not in use to prevent access from unauthorized persons.

c. State only: This policy covers, in part, U.S. Department of State personal property provided to contractors (government-furnished property (GFP)) and contractor acquired property (CAP), when the U.S. Government holds title. See the Federal Acquisition Regulation (FAR) 48 CFR 45.000 and the property clause at 48 CFR 52.245-1 that contractors must follow for U.S. Government owned or leased property held by the contractor.

d. State only: State also provides GFP to grantees. Governing policies and regulations for U.S. Government furnished personal property to grantees are available from the Federal Assistance Division, Office of the Procurement Executive (A/OPE/FA) Federal Grant Regulations SharePoint site.

14 FAH-1 H-312 RECEIVING and Acceptance

(CT:PPM-34; 10-28-2020)

(State/USAID)

a. Receiving is an important function in the property management lifecycle. Property is delivered because posts/bureaus initiated an earlier action to acquire the property. To complete the acquisition process, posts/bureaus must both "inspect" and document "acceptance", including property ordered with a purchase card, as appropriate (reference "Acceptance" at 48 CFR 46.501 and 14 FAH-2 H-523.3).

b. The function of “acceptance” or "rejection" of goods (property) and services on behalf of the U.S. government is an inherently governmental function that must be performed by U.S. Government employee receiving official. Additionally, acceptance must be performed in a timely manner so that the U.S. Government can make payment to the vendor for “acceptable” items within the timeframes that the Prompt Payment Act (31 U.S.C. 3901 through 31 U.S.C. 3907) allows without incurring interest penalties and still obtain any discounts allowed.

c. Federal Acquisition Regulation (FAR) 48 CFR 2.101 states "Inspection means examining and testing supplies or services (including, when appropriate, raw materials, components, and intermediate assemblies) to determine whether they conform to contract requirements."

d. 31 U.S.C. 3901 requires a “payment due date” and the date that any late payment interest penalty must begin to accrue as the later of the:

(1) Receipt of a “proper invoice”; or

(2) The 7th day after date on which property is actually delivered; unless:

(a) The agency has actually accepted such property before such 7th day; or

(b) The contract specifies a longer acceptance period to afford the agency a practicable opportunity to inspect and test the property furnished.

e. No interest penalty is required on a payment due to a valid dispute or for a period during which the dispute is being resolved. See 31 U.S.C. 3901 through 3907 and 5 CFR 1315, “Prompt Payment” implementing government wide regulations. Also, the U.S. Department of Treasury maintains a prompt payment Internet site that provides the applicable interest rates and other tools.

f. U.S. Government receiving is performed by Department of State-designated receiving officials at central receiving locations at foreign posts and domestic bureaus/offices. Receiving also occurs by:

(1) Certified appointed contracting officer representatives (COR) (reference 14 FAH-2 H-142 b(8)), including appointed property administrators (reference 14 FAH-2 H-147.1) for contracts;

(2) Grants officers who administer grants, and

(3) U.S. Government employee credit purchase card holders in accordance with their delegated authorities.

g. A U.S. Government employee must be designated in writing (see 14 FAM 413.1) to serve as the receiving official. The accountable property officer (APO) must establish detailed written procedures that address the receiving, inspection and acceptance functions. The written procedures must then be provided to the U.S. Government employees designated to perform the receiving functions (i.e., receiving official). Generally, the position description of the receiving official contains the written designation of the receiving responsibility. In instances where an employee is occasionally assigned to receive, e.g., in emergencies, and authorization does not exist in the form of a position description, the employee must be given a memorandum authorizing him or her to receive and accept property on behalf of the U.S. Government. Employees without written authorization must not be permitted to sign for acceptance of property deliveries.

h. If a FSN is direct hired or hired under a personal services agreement (22 U.S.C. 2669(c) and 22 U.S.C. 2669(n)) then the post management officer (PMO) may designate in writing the FSN as a receiving official. The receiving official could be a full-time equivalent (FTE); a when actually employed (WAE) retired Foreign Service officer or former Civil Service employee; a temporary hire; or a personal services contractor (PSC) hired under a domestic personal services contract or post issued personal services agreement (PSA). The person could also be locally employed staff (LES) at post. Contractors (other than PSCs) are not eligible to sign as "acceptance" of goods (personal property) or services for the U.S. Government. However, they may support the U.S. Government employee designated in writing as the receiving official by performing inspection tasks as to quantity, quality and condition; subject to appropriate oversight, spot inspection and review by a U.S. Government employee in order to make the acceptance decision.

i. All incoming shipments must be processed within 7 calendar days and a weekly written status report must be provided to the APO on all material remaining in the receiving area beyond the 7 calendar days.

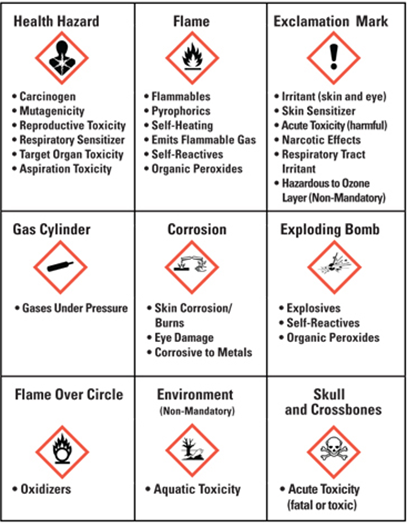

j. If a hazardous commodity is received, a Material Safety Data Sheet (MSDS) or Safety Data Sheet (SDS) must accompany the product explaining what the material is, its health and physical hazards, how to handle it safely, and what should be done in the event of a spill or other accident. For further guidance refer to 14 FAH-1 H-313.2-15, Hazardous Materials.

k. Domestic State only: Receiving authorization: Custodial officers and accountable property officers (APOs) are authorized to sign for incoming personal property, including program property. In a building with multiple custodial officers the APO may designate a primary custodial officer with authority to sign for deliveries destined for multiple areas in the building. U.S. Government contractors (other than PSCs) are not authorized to sign "acceptance" for personal property, including program property.

14 FAH-1 H-312.1 Receiving Areas

(CT:PPM-22; 03-03-2016)

(State/USAID)

To the extent feasible, the receiving activity location must be centralized (see 14 FAM 413.2). Central receiving provides more effective control of U.S. Government property through the efficient use of qualified receiving personnel. The senior receiving official must be located in the centralized receiving area. Enforcing procedures to ensure that deliveries are properly documented upon "acceptance" is more effective with centralized receiving.

14 FAH-1 H-312.1-1 Alternate Receiving Area

(CT:PPM-22; 03-03-2016)

(State/USAID)

The designation of a central receiving area does not preclude inspection and "acceptance" at other locations when advantageous to the U.S. Government. When diversified activities make total centralization of receiving activities impractical, alternate receiving areas may exist at the most beneficial locations. The accountable property officer (APO) may elect to have smaller packages delivered to the general services office instead of to the central receiving area. However, in those instances, there should be a minimum number of alternate sites, and as many shipments as practicable should go to the central receiving area.

14 FAH-1 H-312.1-2 One Time Receiving

(CT:PPM-22; 03-03-2016)

(State/USAID)

If it is necessary that delivery occur on a one time basis, to a location that is not one of the normal alternate receiving areas (e.g., delivery of a generator directly to a residence), the accountable property officer (APO) must ensure that the shipment is properly received and "acceptance" signed for, and that the appropriate receiving and inspection document is prepared and distributed (see 14 FAM 413.5).

14 FAH-1 H-312.2 Receiving Responsibility

14 FAH-1 H-312.2-1 Central Receiving Area

(CT:PPM-22; 03-03-2016)

(State/USAID)

To ensure effective control and protection of all incoming property, the accountable property officer (APO) designates, in writing, a specific U.S. Government employee to serve as the primary receiving official who will function in the main receiving area. The function of the receiving official is to inspect and after acceptance, sign for incoming property using the Integrated Logistics Management System (ILMS) Asset Management (AM) Final Receipt Module. If there is only one receiving official, provision must be made for an alternate to serve in the receiving official's absence. The alternate must inspect and after acceptance sign for shipments only in the absence of the primary receiving official.

14 FAH-1 H-312.2-2 Alternate Receiving Area

(CT:PPM-22; 03-03-2016)

(State/USAID)

When establishing an alternate receiving area, the accountable property officer (APO) must coordinate with the head of the office where the alternate receiving area is located to designate an employee in that office to function as a receiving official. Provision must also exist for an alternate to serve in that employee's absence. The APO must then provide the receiving official with a memorandum authorizing him or her to perform the receiving duties. The receiving official must receive all incoming property partial or in full through the Integrated Logistics Management System (ILMS) Asset Management (AM) Final Receipt Module. The accountable property officer (APO) must provide a set of written instructions on how these duties should be performed (e.g., required time frame for processing incoming deliveries, how to prepare receiving reports, receiving report copy distribution, and how to report discrepancies) must also be provided.

14 FAH-1 H-312.3 Receiving Files

(CT:PPM-22; 03-03-2016)

(State/USAID)

The control of documents used in the receiving process is essential to effective receiving operations. Pending order files of acquisition documents (copies of purchase orders, contracts, transfer documents, or requisitions) must be established at each receiving area. Copies of all advance bills of lading should also be forwarded to the receiving area. As shipments are received and each acquisition document is completed (i.e., receiving reports are on file confirming that all items listed on the acquisition document have been received, or actions on damaged or missing property have been completed), all documents in that file are transferred to a completed file. If an alternate receiving area has been established, the completed receiving files for the alternate receiving area must be filed into the central receiving area’s completed files.

14 FAH-1 H-312.3-1 Receiving File Documents

(CT:PPM-22; 03-03-2016)

(State/USAID)

a. It is the responsibility of the accountable property officer (APO) that written procedures ensure that copies of requisitions, purchase orders, shipping notices, bills of lading, and any other shipment related documents are sent to the appropriate receiving area so that a "due in" file can be established. Should the appropriate receiving official not receive copies of these documents, receiving official will not know what or how much property to expect. If all receiving reports are to be prepared at the central receiving area, the central receiving area must also receive a copy of the acquisition document for shipments consigned to the alternate receiving area.

b. Written instructions must be made available to the receiving official to provide guidance for those times when an acquisition document may not reach the receiving area.

14 FAH-1 H-312.3-2 Establishing Files

(CT:PPM-22; 03-03-2016)

(State/USAID)

A separate folder must exist for each acquisition document (and related shipping documents) and the folders filed in numerical order, in accordance with the acquisition document number, by fiscal year.

14 FAH-1 H-312.3-3 Receiving Reports

(CT:PPM-22; 03-03-2016)

(State/USAID)

The receipt of all property partial or in full at post or bureaus/offices must be received through the Integrated Logistics Management System (ILMS) Asset Management (AM) final receipt module. This will ensure Form DS-127, Receiving and Inspection Report, will be auto created in ILMS.

14 FAH-1 H-312.3-4 Completed Files

(CT:PPM-22; 03-03-2016)

(State/USAID)

Completed centralized receiving files should be established and maintained in the central receiving office and, when delivery is complete, the pending file is transferred to the completed files. The receiving official in the receiving area should forward complete copies to the central receiving area for permanent filing. A completed file may be disposed of three years after the final delivery to the order has been made.

14 FAH-1 H-312.3-5 File Reconciliation

(CT:PPM-22; 03-03-2016)

(State/USAID)

The receiving official must inform the procurement office of any pending orders, or partial orders, in the "due in" file for which the delivery date has already passed. The status of these orders should be researched and resolved.

14 FAH-1 H-312.4 Receiving Actions

14 FAH-1 H-312.4-1 Checking the Seal

(CT:PPM-22; 03-03-2016)

(State/USAID)

The receiving official must ensure upon the arrival of a sealed container (e.g., box, carton, etc.) that the seal is verified as not to have been tampered with, the condition of the item must be checked, and the serial number verified before the carrier is opened. If the seal is broken, missing, shows evidence of having been tampered with, or the serial number does not agree with that listed on transportation documents, the receiving official must make a notation on Form DS-127, Receiving and Inspection Report, and, in the case of sensitive/classified cargo, the post security officer notified.

14 FAH-1 H-312.4-2 Unloading

(CT:PPM-50; 10-16-2024)

(State/USAID)

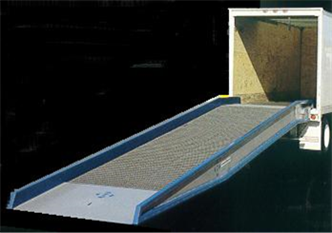

a. The method of entry into the carrier (see example loading dock equipment below) depends upon the type of carrier, type of material received, and the physical characteristics of the receiving area. If unloading occurs at a warehouse platform, a bridge plate or some type of mechanical or hydraulic dock leveler may be used to move material handling equipment into the carrier. If no raised platform exists, a portable platform ramp may be used to move material handling equipment into the carrier. However, if material handling equipment is to enter the truck, the floor strength of the truck must be checked to ensure that the floor can support the weight of the equipment and the load.

b. When containers are fully packed with quantities indicated on the outside, they need not be opened during the inspection process, unless there is evidence of having been tampered with, or of damage. If large quantities of the same kinds of items are to be stored in a palletized (to place on pallets) bulk storage area, it is generally wise to palletize these items while they are still in the carrier or as they are offloaded from the carrier.

c. Immediately report ruptured or damaged containers of hazardous supply items to the warehouse supervisor in order to ensure proper handling and to avoid any risk of injury to personnel. If containers leak flammable liquids, they must be safeguarded to prevent the creation of a serious fire hazard.

|

Example: Loading dock equipment |

|

|

loading ramp

|

bridge plate

|

|

|

|

|

Example: dock leveler

. |

14 FAH-1 H-312.4-3 Delivery Inspection of Property

(CT:PPM-22; 03-03-2016)

(State/USAID)

a. Prior to receiving official signing for delivery, each shipment must be physically checked against the incoming transportation documents (e.g., freight bill, bill of lading, etc.), to verify receipt of the correct number of pieces, and must be inspected for external damage. This action should occur concurrently with the unloading operation. If a U.S. Government consolidation or freight-forwarding contractor initially received a shipment, the signature of the U.S. Government employee designated as the receiving official acknowledges initial receipt on behalf of the U.S. Government. Therefore, all shipments must be accurately checked to protect fully the interests of the U.S. Government to prevent the U.S. Government from incurring liability for items that are missing, damaged or do not meet quality requirements.

b. The following steps should be taken when inspecting material:

(1) Remove any packing slips attached to containers;

(2) Check the packing slip and shipping document(s) for a purchase order number, contract number, requisition number, or any number that can be matched against the acquisition document in the "due-in" file;

(3) Count the number of pieces listed on the carrier's transportation document and compare that count with the pieces unloaded from the carrier. If the count agrees, sign for the shipment and release the carrier;

(4) If a chemical product, ensure that a material safety data sheet (MSDS) or safety data sheet (SDS) is provided and a copy is directed to the proper location identified for the facility in compliance with the hazard communication program;

(5) In cases where the total quantity of pieces tallied on the shipment does not match the quantity the shipping document lists, bill of lading, and/or packing list covering the shipment, the pieces should be recounted before indicating the quantity actually received;

(6) External damage can be caused by mishandling, cargo shifting, dropping, tampering, or from natural causes (rain, etc.). Where external damage is evident, containers (packages, cartons, cases, etc.) should be opened to determine the extent of the damage or shortage. It is preferable that this inspection be performed in the presence of the carrier's or shipper's representative. List the specific details of the damage on the carrier's copy and the receiving office's copy of the delivery document. If damage to technical equipment or parts is suspected, a technician should examine the property. If possible, this should occur before the carrier's delivery document is signed. Any damaged container should remain at the receiving location premises until an agreement with the shipper or carrier has been reached. Digital photographs are extremely valuable and should be used when details of the discrepancy cannot be adequately explained in writing or can be more fully supported by such evidence. The date that the photographs were taken, along with the delivery document number and carrier identification, should be noted on the back of the photographs;

(7) The extent of any discrepancies discovered, such as damage or shortage, must be noted on the carrier's copy and receiving office’s copy of the transportation document that is then signed and dated by the receiving official. If space is lacking on the transportation document, include the statement, ”SEE REVERSE SIDE,” on the front, and provide the information in detail on the reverse. The carrier operator must initial any discrepancy notations on the receiving office copy. Failure to do so may jeopardize the right to recovery from the carrier in the event it is determined that damage was sustained in transit;

(8) Verify that all items delivered are addressed correctly;

(9) If it is not possible to make an internal inspection while the carrier waits, include the statement, "Complete acceptance of this shipment depends on an internal inspection," on the carrier's copy and the receiving office copy of the delivery document; and

(10) The receipt of all personal and program property must be received utilizing the Integrated Logistics Management (ILMS) Asset Management (AM) Final Receipt module. This will ensure an asset record and an automated DS-127 receiving and inspection report are created.

14 FAH-1 H-312.4-4 Concealed Shortage or Damage

(CT:PPM-22; 03-03-2016)

(State/USAID)

In instances where concealed loss or damage is not discovered until after the shipment has been accepted, the carrier's agent should be notified immediately, and be given an opportunity to inspect the property. Oral notification should be confirmed, in writing, listing the items in question and indicating any identifying markings. The carrier must be provided with copies of the delivery documents and should be requested to inspect the property. A copy of the carrier's inspection report is retained in the shipping office files.

14 FAH-1 H-312.4-5 Holding Damaged Property

(CT:PPM-22; 03-03-2016)

(State/USAID)

Damaged property should not be processed and recorded on property records but must be segregated and held by the warehouse staff for disposition, pending final determination of liability. Warehouse personnel should exercise the same care of such property as given to U.S. Government property, until the carrier or other responsible party disposes of the property. All damaged property returned to the carrier, or otherwise disposed of in accordance with instructions from the carrier or other responsible party, must be properly documented to record actions taken.

14 FAH-1 H-312.5 Inspection

14 FAH-1 H-312.5-1 General Inspection

(CT:PPM-22; 03-03-2016)

(State Only)

a. Immediately after delivery has been made, material received must be completely checked against the covering acquisition document and the packing list to verify commodity, quantity, quality and condition. Expendable supply items received in unopened cartons, with the quantity clearly marked on the outside, need not be opened, unless there is evidence of having been tampered with or of damage. Otherwise, cartons should be opened and inspected. Appliances should be tested to ensure they operate normally.

b. Check the packing list to make certain that everything shipped has been received.

c. If inspection reveals discrepancies including damages, overages, or items that do not meet specifications (including counterfeit items) the property in question should be set aside until disposition instructions are received from the accountable property officer (APO).

14 FAH-1 H-312.5-2 Delayed Inspection

(CT:PPM-22; 03-03-2016)

(State Only)

If inspection is not immediately possible, the material should be placed in a holding area near the receiving area until receiving action can be accomplished. Deliveries in the holding area should be inspected and received within 3 working days. In this instance, the shipment should be kept intact, completely separated from other material, and protected from pilfering. If possible, the holding area should be a secured area.

14 FAH-1 H-312.5-3 Special Inspection Requirements

(CT:PPM-22; 03-03-2016)

(State Only)

When shipments contain property that may require a specialized inspection to be performed, if necessary, the receiving official should arrange for a prompt inspection by a qualified technical expert. In these instances, the receiving official should sign the receiving report as "acceptance" once the appropriate tests have verified the technical requirements have been met. Documentation of the test(s) performed and the actual results must be provided by the technical expert. Examples include aircraft fasteners that must be to a certain strength before breaking and are controlled by manufacturer lot number, or ammunition that must have certain levels of power or characteristics when actually fired.

14 FAH-1 H-312.5-4 Purchase Card Purchases

(CT:PPM-29; 04-19-2019)

(State Only)

a. Individuals making purchase card or petty cash purchases perform the initial inspection at the time the purchase is made at a vendor site. Otherwise, if delivery is required the property should be processed through the central receiving location or alternate delivery site as appropriate.

b. Information on discrepancies on credit card purchase must be provided to the purchase cardholder to attempt to resolve the dispute directly with the vendor. If attempts to resolve a charge with a vendor are not successful, the cardholder must complete a Citibank dispute form and directly notify Citibank.

c. All disputes unresolved at the supplier, cardholder level must be submitted to Citibank within 60 calendar days from the date that the charge(s) first appeared on the cardholder statement of account. After 60 days, the right to dispute a charge may be relinquished. Sales tax, if incurred, is not considered a disputable charge. The cardholder must provide a copy of the dispute for the designated billing office (DBO - FMO).

d. The cardholder must respond promptly to Citibank requests for additional information or completion of an affidavit for the disputed charge and provide to Citibank. Late submission of this information may result in lost rights under the dispute process.

e. Cardholders must retain:

(1) A copy of the dispute transmittal showing it was successfully received by Citibank; and

(2) A copy of the dispute form and the affidavit (if applicable) in the file for a period of 3 years.

f. The cardholder must track any credits resulting from a dispute on future statements and coordinate closely with designated billing office. If the credit does not appear on the statement in a timely fashion, the cardholder must contact Citibank directly.

14 FAH-1 H-312.5-5 Cash on Delivery Shipments

(CT:PPM-22; 03-03-2016)

(State Only)

Cash on delivery (C.O.D.) shipments may be received and paid for before the examination and any necessary quality, quantity, or condition adjustments may be settled later with the vendor. However, when receiving such shipments, a statement must be in writing on the delivery document to the effect that the receipt is subject to inspection and verification.

14 FAH-1 H-312.6 Reporting Receipts

14 FAH-1 H-312.6-1 Receiving Document

(CT:PPM-22; 03-03-2016)

(State/USAID)

a. So that a working document is available for the completion of purchase or requisition files, payment of invoices, and the updating of property records, reports on the quantity and condition of all property received (including damaged or otherwise unusable property) must be prepared. The report is prepared in English, the item cost indicated in U.S. currency, and the report signed by the receiving official authorized to determine "acceptance" of the property on behalf of the U.S. Government. Reports must be prepared for individual items, not for sets, such as a "set of furniture." Form DS-127, Receiving and Inspection Report, is the Department and USAID's official document for recording the receipt and acceptance of property.

b. When a total property order is received either partial or in full, it must be received using the Integrated Logistics Management System (ILMS) Asset Management (AM) final receipt module.

c. USAID only: USAID missions must use the ILMS as the approved personal property management system. At any mission that ILMS has not been deployed, BARSCAN (the USAID predecessor personal property management system may be used) until such time as ILMS is deployed at that respective USAID mission.

14 FAH-1 H-312.6-2 Receiving and Inspection Report Criteria

(CT:PPM-22; 03-03-2016)

(State/USAID)

a. Because of the need for different offices to use Form DS-127, Receiving and Inspection Report, as an action document, the report must be prepared in a way that will service all action offices. For example, if property ordered on separate acquisition documents is delivered in the same shipment, a separate Form DS-127 must be prepared for each acquisition document.

b. When creating receiving reports:

(1) Information from the acquisition document can be used for proper nomenclature and descriptive data;

(2) Do not combine items from more than one acquisition document on a single report;

(3) Do not include property received on different days on a single report. The exact date of receipt must be reported;

(4) Do not mix property that belongs to more than one U.S. Government agency on a single report. If quantities are commingled on the same report, the property records official cannot identify ownership; and

(5) Do not mix expendable and nonexpendable property on a single report.

14 FAH-1 H-312.6-3 Prompt Payment

(CT:PPM-22; 03-03-2016)

(State/USAID)

The receiving document must be executed promptly in accordance with the time frames of the prompt payment act, and immediately furnished to the designated payment office. Once the property is accepted and signed for, the vendor is free to submit an invoice for payment. The paying office's authority for paying the invoice is the receiving and inspection report (i.e. completed and signed Form DS-127). Therefore, it is important that little time elapse between the signing for property acceptance and the processing of Form DS-127. For items received by the U.S. Despatch Agent (USDA), payment is due to the contractor based on the USDA receipt, rather than receipt of the item(s) at the post.

14 FAH-1 H-312.6-4 Partial and Late Deliveries

(CT:PPM-22; 03-03-2016)

(State/USAID)

a. When items are received late beyond the terms of the acquisition, especially under a contract, work with the contracting officer and acquiring organization to determine if partial delivery is acceptable and if consideration for late delivery should be obtained. This is a business decision that should be made based on the facts and circumstances.

b. The U.S. Government has the right to consideration for late delivery. Property that is delivered with a minor deviation from the schedule with no adverse effect to U.S. Government operations may not be worth the time it would take to negotiate consideration. If delivery or performance is critical to mission success, the contracting officer should consider the addition of deductions or liquidated damages to compensate the U.S. Government for delays.

c. If partial deliveries are received at various times, several receiving reports may be prepared for items on a single acquisition document. Since there is a need to add accepted property to the property records as soon as possible, and an obligation to pay the valid invoice promptly, receiving reports must also be prepared for partial deliveries as they are received. However, authorized receiving official approving "acceptance" of partial deliveries must remain cautious of improper product substitution or charging for items not delivered.

14 FAH-1 H-312.7 ILMS Receiving Process

(CT:PPM-22; 03-03-2016)

(State/USAID)

Use the Integrated Logistics Management System (ILMS) to generate the DS-127, Receiving and Inspection Report. At a minimum, the data included on such a report must include:

(1) Consignor and/or contractor;

(2) Purchase order/requisition/transfer document/contract/or job number;

(3) Ordering document funds data (when appropriate);

(4) Stock number (when appropriate);

(5) Description;

(6) Quantity received by line;

(7) Unit of issue;

(8) Unit price;

(9) Total cost by line;

(10) Serial numbers of items, if applicable;

(11) Certification of "acceptance" by the U.S. Government;

(12) Signature of authorized U.S. Government employee receiving official performing "acceptance"; and

(13) Date of receipt.

14 FAH-1 H-312.7-1 ILMS Receiving Reports

14 FAH-1 H-312.7-1(A) ILMS General Receiving Process

(CT:PPM-34; 10-28-2020)

(State/USAID)

a. Any deviations from the acquisition document copy (i.e., ILMS-Ariba) in the receiving file from what was actually received must be noted on the receiving report. All property received in a damaged condition must also be noted on the report.

b. In addition to the description, all identifying numbers (manufacturer stock and/ or part numbers, model numbers, serial numbers, and U.S. Government barcode tag numbers) must be included on the report for accountable property contained in 14 FAM 411.4.

c. When they can be identified, transportation charges must be included on the receiving report. If possible, they should be broken down by line, and listed as a separate item under each line.

NOTE: Transportation cost, purchase cost, installation cost and any other cost to get the property to its place and set up for first use all become part of the "acquisition cost" which is often used to determine Department accountable property and if the property meets the Department capitalization criteria. See 14 FAM 411.4 definitions for acquisition cost and accountable property.

d. Reference the ILMS tutorials for completing the Form DS-127, Receiving and Inspection Report through the final receipt process.

14 FAH-1 H-312.7-1(B) Form DS-127 Distribution Using ILMS

(CT:PPM-39; 04-13-2021)

(State/USAID)

a. The distribution of the Form DS-127, Receiving and Inspection Report, is an automated process in ILMS. It is maintained electronically for six years (see General Record Schedule 1.1, Financial Management and Reporting Records item 010: Financial transaction records related to procuring goods and services, paying bills, collecting debts; Disposition authority: DAA-GRS 2013-0003-0001). At a minimum, the following personnel or office have access to view and obtain relevant completed DS-127 forms:

(1) Accountable property officer;

(2) The financial management office or USAID controller, as appropriate;

(3) Receiving office files; and

(4) For USAID security property, send one copy to SEC/PSP: Picture Captions.

b. Domestic State only: The custodial officer (CO) distributes copies of Form DS-127 as follows:

(1) Copy to the Logistics Management Office; and

(2) Copy to the APO.

14 FAH-1 H-312.8 Actions After Receiving

(CT:PPM-34; 10-28-2020)

(State/USAID)

a. After completing the receiving action, additional actions are necessary. Label incoming accountable property with the Department barcode number identification as appropriate. See 14 FAM 414.1 for accountability including program property and 14 FAM 411.4 definitions for accountable property and acquisition cost. Exclude leased property which should not be labeled with agency barcode number identification.

b. Review property to identify if hazardous or special storage requirements are necessary.

c. Review property shelf-life to ensure assets with a shelf-life are utilized or processed for disposition prior to the shelf-life expiration date or extended shelf-life determination, and that this is properly recorded. See 41 CFR 101-27.201 for establishment of controls for shelf-life items to minimize loss and ensure maximum use prior to deterioration. In order to assure maximum use of shelf-life items, the receiving official must:

(1) Identify shelf-life items, including any new items to be placed in inventory, which have a limited shelf-life period;

(2) Establish the shelf-life period of such items and procedures for controlling their procurement, storage, and issue; and

(3) Inspect or test certain shelf-life items prior to deterioration to determine if the shelf life may be extended. Shelf-life items are classified as nonexpendable (Type I) and expendable (Type II):

(a) Type I items have a definite storage life after which the item or material is considered to be no longer usable for its primary function and should be discarded. Examples of Type I items are drugs and medicines with certain characteristics; and

(b) Type II items are those items for which successive re-inspection dates can be established when the items have a continued usability as determined by examination based upon criteria that have been agreed upon. An example of type III item is paint;

(4) Conduct inventory management analysis to determine if shelf-life stocks are expected to be utilized prior to the expiration of the original or extended shelf-life period; and

(5) If not processed for disposal, process for potential use by other U.S. Government agencies or competitive public sales prior to the expiration date.

d. If property is classified as hazardous refer to 14 FAH-1 H-313.1-3, Hazardous Commodities.

e. Mobile phones State only: A designated receiving official must perform receiving and acceptance of State-owned or -leased mobile phones in accordance with 14 FAH-1 H-312 requirements and create the mobile phone asset record in the ILMS loanable property (LP) module, irrespective of cost thresholds. State-owned or leased-mobile phones are not required to be barcoded.

(1) All State owned or leased mobile phones are considered sensitive property, both as information-technology equipment with memory capability and communication equipment, however, mobile phones are not required to be barcoded and accounted for in ILMS-Asset Management (AM).

(2) Instead, the bureau, office, or post must use the ILMS-Loanable Property (LP) module to control mobile phones and either loan (90 days or less) or issue (greater than 90 days) these phones to employees.

14 FAH-1 H-312.8-1 Labeling U.S. Government Agency Ownership

(CT:PPM-34; 10-28-2020)

(State/USAID)

a. All property must be marked to indicate ownership as soon as possible after receipt and acceptance, which is generally the U.S. Government agency that funded the purchase. The receiving official must do such labeling before the property is delivered directly to the user office or moved to a storage location in the warehouse. The receiving official should also apply a barcode label to any property and create the initial asset record in the ILMS Asset Management (AM) module. This will ensure that any accountable property received will be reflected on the property records, including all property stored in a warehouse.

b. Mobile phones State only: A designated receiving official must perform receiving and acceptance of State owned or leased mobile phones and create the mobile phone asset record in the ILMS loanable property (LP) module, irrespective of cost thresholds. State owned or leased mobile phones are not required to be barcoded.

14 FAH-1 H-312.8-2 Agency Identification

(CT:PPM-22; 03-03-2016)

(State/USAID)

a. Incoming property may belong to different U.S. Government agencies. Therefore, property must be easily identified. To prevent commingling and to facilitate identification, the property should be marked to show the specific U.S. Government agency ownership. This can be done with tags or labels bearing the various U.S. Government agency names. When marking the property, care should be taken to not ruin the appearance of the item or cause damage to the property. The mark should be inconspicuous but easily located. Avoid putting the identification on removable parts such as drawers. The markings need to easily be removed since all markings of U.S. Government ownership must be removed during the disposition stages; including when property is transferred to another U.S. Government agency for further use.

b. Leased property should not be labeled with agency identification.

c. Property received with identified discrepancies from the acquisition requirement, including damage or otherwise unusable should not be labeled immediately, because it might be returned to the supplier. It should be set aside until disposition instructions are received from the accountable property officer (APO).

14 FAH-1 H-312.8-3 Barcode Label (State and USAID)

(CT:PPM-34; 10-28-2020)

(State/USAID)

a. All accountable property received must be entered onto the property records. Use ILMS for each accountable property item and ensure the property receives an appropriate barcode label, if applicable. State-owned or -leased mobile phones are not required to be barcoded and are controlled in ILMS loanable property (LM) module not ILMS asset management module.

b. The receiving official should maintain a supply of pre-numbered barcode labels, plus procedures that include the identification of current items to be labeled, and instructions on the placement of the barcode label. When selecting barcode labels, the receiving official should select numbers in sequence. Barcode numbers should not be selected at random.

c. To facilitate an efficient physical inventory, proper placement of barcode labels is important. The labels should be placed in a location that is easily found and conveniently accessible for barcode scanning. However, discretion must be used so that the appearance of the property is not adversely affected. Placing the barcode label should be consistent with each item, (i.e., always in the same place on all dining room chairs, etc.) so that the inventory teams will know where to look during a physical inventory. Avoid putting the barcode label on removable parts such as drawers. Ensure that office furniture in storage within a warehouse is barcoded; but office furniture (systems furniture, office chairs, filing cabinets, etc.) going directly to office space for use does not need a barcode label, since it is not accountable property while in use within an office and is not required to be inventoried.

d. In some instances, a property item can be inspected without taking it completely out of the carton. Often, however, a barcode label cannot be properly affixed to the property while it is still in the carton. If the property is to remain in the carton to be stored in a warehouse, a barcode number must be assigned so that the item can be picked up on the property records. In this case, assign a barcode number, mark the number on the case with a felt marking pen, place the barcode label in a small plastic bag or an adhesive-backed packing list envelope, both of which are available for purchase from the General Services Administration (GSA) using GSAAdvantage for office supplies, and affix the bag or envelope to the carton. At the time the property is removed from the carton to be issued for use, the barcode number should be affixed. If the bag is accidentally knocked off and lost during storage, the stenciled barcode number will allow access to the item's property record in ILMS, in order to assign a new barcode number.

e. Property received with identified discrepancies from the acquisition requirement, including in a damaged or unusable condition, should not be barcode labeled immediately. Such property might be returned to the supplier. It should be set aside until disposition instructions are received from the APO.

14 FAH-1 H-312.8-4 State Receiving Worksheet for Nonexpendable Property

(CT:PPM-50; 10-16-2024)

(State Only)

a. As each barcode label is affixed to the property the Form DS-1955, Receiving Worksheet for Nonexpendable Property, may be used as a supplemental form to collect the needed data to enter the Integrated Logistics Management System (ILMS) Asset Management (AM) Final Receipt module. The Form DS-1955 is not to replace the DS-127 Receiving and Inspection Report.

b. So that the data entry person is provided with all the necessary information, the APO should ensure that the worksheet is reviewed and that as many of the remaining required data fields as possible be completed before data entry. This is especially true when the APO reviews information for capitalized property to ensure the accuracy of the fund, cost, and other pertinent data.

c. Form DS-1955 should not be immediately prepared for property received with identified discrepancies from the acquisition requirement, including in a damaged or unusable condition. Such property might be returned to the supplier. It should be set aside until the APO issues disposition instructions.

14 FAH-1 H-312.9 Reporting Shipment Discrepancies

(CT:PPM-22; 03-03-2016)

(State/USAID)

a. The importance of recording all of the details related to shipment discrepancies becomes apparent when it is necessary to file a claim for missing or damaged property. The decision to file a claim should be based on whether the administrative costs for such an action are commensurate with the value of the property received. In some instances, it might be more economical to dispose of the property or to have it repaired.

b. Timely reporting of the discrepancies to the supplier is critical, but must be made within 30 days from date of delivery receipt.

14 FAH-1 H-312.9-1 Shipping-Type Discrepancies

(CT:PPM-22; 03-03-2016)

(State/USAID)

A shipping-type discrepancy is any variation in quantity, quality, or condition of property received from that shown on the packing list or acquisition document.

14 FAH-1 H-312.9-2 General Services Administration (GSA)/Department of Defense (DOD) Report of Discrepancy (ROD)

(CT:PPM-22; 03-03-2016)

(State/USAID)

a. If the shipment is from a General Services Administration (GSA) supply distribution point or is directed by GSA from a vendor, a report should be made, regardless of the cost. Form SF-364, Report of Discrepancy (ROD), should be prepared and the original and two copies should be sent within 15 calendar days from receipt of shipment to the GSA Discrepancy Reports Center, 1500 E. Bannister Road, Kansas City, MO 64131.

b. Customers who have shipping, transportation, or billing discrepancies on national stock number (NSN) items should view their order status history in GSA Advantage and locate the item and selected the requisition number. Customers will then be taken to a report that allows them to indicate the type of discrepancy, and directly submit the discrepancy report.

c. If the shipment is from a Department of Defense (DOD) activity or is directed by DOD from a vendor, a report should be made if the value of the discrepant material is one hundred dollars or more (or regardless of cost if a DOD vendor ships directly). Form SF-364, Report of Discrepancy (ROD), should be prepared and the original and one copy should be sent to the DOD activity to which the original order was submitted. If the shipment was from a vendor, attach a copy of the vendor's shipping document.

14 FAH-1 H-312.9-3 U.S. Government Agencies Other than General Services Administration (GSA) or Department of Defense (DOD)

(CT:PPM-22; 03-03-2016)

(State/USAID)

If the supplier is a U.S. Government agency other than the General Services Administration (GSA) or the Department of Defense (DOD), the discrepancy must be reported directly to that agency. If the problem is not satisfactorily resolved and assistance is needed, a request for assistance may be submitted to your regional logistics liaison officer located at the U.S. Despatch Agency.

14 FAH-1 H-312.9-4 Commercially Originated Shipments (Other than General Services Administration (GSA) or Department of Defense (DOD)-Directed)

(CT:PPM-22; 03-03-2016)

(State/USAID)

If the shipment is from a commercial source, the discrepancy must be reported directly to the vendor.

14 FAH-1 H-312.9-5 Controlled Substances - Narcotics

(CT:PPM-22; 03-03-2016)

(State/USAID)

a. If there has been a failure to deliver narcotics that have been shipped, regardless of the dollar value, it must be reported immediately to the supplier and Despatch Agent with a request that the suppler inform the Drug Enforcement Administration (DEA), if required.

b. See 21 CFR 1301.74(c) requirement for registrants to notify the DEA in writing, of the theft or significant loss of any controlled substance within one business day of discovery of such loss or theft. The supplier is responsible for reporting all in-transit losses of controlled substances by the common or contract carrier within one business day of discovery of such theft or loss.

c. The DEA Form 106, Report of Theft or Loss of Controlled Substances is submitted to DEA online.

14 FAH-1 H-312.9-6 Transportation Type Discrepancies

(CT:PPM-22; 03-03-2016)

(State/USAID)

A transportation-type discrepancy is any variation in quantity, as it relates to package count in pieces of freight or condition of material received from that shown on the bill of lading or other transportation document. When reporting transportation type discrepancies, photographs are extremely valuable and must be used when details of the discrepancy cannot be adequately explained in writing or can be more fully supported by such evidence.

14 FAH-1 H-312.9-6(A) Shipments through a Consolidated Receiving Point

(CT:PPM-22; 03-03-2016)

(State/USAID)

a. Determine where the discrepancy occurred. To determine the proper action to be taken when loss or damage to incoming shipments is discovered, the authorized receiving official performing receiving functions must establish whether the damage occurred before or after the shipment arrived at the port of entry. Refer to the bill(s) of lading and/or the delivery receipts to ascertain where the first notation concerning the loss or damage was made. The first notation will place the responsibility, and the receiving official must act accordingly.

b. Loss or damage before arrival at port of entry: If the initial discrepancy note was made by the ocean carrier upon receipt of the shipment, contact the Despatch Agent. If the initial notation was made by an inspector at the port of entry, a claim must be filed with the carrier. If this is not possible, or if assistance is required, contact the Despatch Agent.

c. Loss or damage after arrival at port of entry: The post is responsible for initiating and effecting settlement of claims directly with the parties responsible for loss or damage occurring after arrival of shipment at the port of entry. These claims will be handled in accordance with local laws and customs. The assistance of a post at the port of entry will be enlisted by inland posts whenever such aid is necessary or will be helpful in reaching a prompt settlement.

14 FAH-1 H-312.9-6(B) Shipments Direct to Posts not in a Consolidation Program

(CT:PPM-22; 03-03-2016)

(State/USAID)

a. General Services Administration (GSA) or Department of Defense (DOD) shipments: If the shipment is made or directed by GSA or by DOD, discrepancies must be immediately reported to GSA or DOD.

b. Supply source other than GSA or DOD: If the shipment was ordered from a supply source other than GSA or DOD, claims for losses or damages must be pursued with that source. Visible damage is generally the result of in-transit damage. If the receiving official is unable to resolve the matter, the regional logistical liaison officer will assist.

14 FAH-1 H-313 Storage OPERATIONS

(CT:PPM-22; 03-03-2016)

(State/USAID)

a. The property management officer (PMO) must implement an efficient, secure, and cost-effective storage program. It is the policy of the Department that property in any warehouse is accounted for at all times and protected against loss or damage or materials being used against us as "weapons of opportunity." Management controls must be in place to prevent loss from damage, theft, or pilferage during receipt, storage, and shipment of U.S Government property.

b. The generally accepted basic fundamentals of modern warehousing are:

(1) Use of a one-story type building;

(2) Use of pallets and materials handling equipment; and

(3) Use of an effective warehouse and storage plan.

14 FAH-1 H-313.1 General Purpose Warehouse

(CT:PPM-22; 03-03-2016)

(State/USAID)

During recent attacks on U.S. facilities, intruders used unsecured mission property as improvised weapons, i.e. weapons of opportunity. To ensure the safety of personnel and property, employees must properly secure and store all materials that can be used as improvised weapons, including, but not limited to, flammable liquids, paint, hand and power tools, rebar, rigid conduit, loose scaffolding, and other loose construction materials or equipment. Such materials must be stored as securely as possible when not in use to prevent access from unauthorized persons.

14 FAH-1 H-313.1-1 Facility Makeup

(CT:PPM-22; 03-03-2016)

(State/USAID)

a. General purpose warehouses include such activities as loose issue and/or bulk storage, receiving, packing, and shipping. The building should be a single- story building with high-bay storage space and a loading dock at truck bed level. A cantilever support canopy over a dock is recommended. In addition to the efficiency and speed typical of a high-bay operation, cost is an important factor to be considered. A high-bay structure generally affords more usable space per dollar of investment than any other. Multi-story buildings are discouraged because of the space requirements for elevators and stairs and the higher cost of a structure of sufficient mechanical strength to support upper-level loads. Be mindful of floor-load capacity. Ensure that the floor will adequately support the weight of your planned racking, stock, and material handling equipment.

b. A truck dock of sufficient width on one side of the general purpose warehouse provides for the loading and unloading of truck hauled property. The matching dock and warehouse floor permit direct access of material handling equipment to and from the warehouse interior, and to and from the interior of carrier conveyance.

14 FAH-1 H-313.1-2 Space Allocation

(CT:PPM-29; 04-19-2019)

(State/USAID)

a. Receiving area: An area large enough to accommodate incoming shipments, that can be used as a work area during the receiving process should be established at the loading dock area. If possible, this area should be physically secured (locked) so that only designated employees can gain admittance. Allowance should be made for receiving more than one delivery at a time.

b. Driver’s waiting area: Truck drivers must be directed to a secure room/area while property is being unloaded. Drivers must not have access to the warehouse facility without sufficient justification and must be accompanied at all times by authorized personnel.

c. Office space: Office space in a general-purpose warehouse is strongly discouraged. Offices require physical protection based on requirements in 12 FAH-6, OSPB Security Standards and Policy Handbook, necessitating additional protection beyond that required for warehouses without offices. Office space requires a two-hour fire resistive construction separation between the hazardous storage area and the office area depending on the size of the hazardous storage areas.

d. Controlled access area: A controlled access area must be established for the protection of sensitive, or highly pilferable property. Depending on the type and quantity of property being protected, this area may be a lockable steel cabinet, or lockable cage, room, or vault. A list of authorized personnel should be posted by the entry.

e. Flammable-items room:

(1) In warehouses intended to include storage of flammable property, special provisions for safe storage of these potentially dangerous materials must exist. Ideally, these supplies should be stored in a separate building equipped with an automatic fire sprinkler system. However, if this is not possible and these supplies are stored in a general-purpose warehouse, flammable property must be stored in a fire-resistant enclosure separated from other supplies by full-height parapeted firewalls and openings equipped with approved fire doors. To provide maximum segregation from other stocks, such a fire-resistant enclosure must be located in a remote section of the building. The room must be in compliance with the latest version of codes and standards of the National Fire Protection Association (NFPA) 30: Flammable and Combustible Liquids Code. The storage location must have immediate access to exterior doors and be readily accessible for firefighting purposes. Adequate explosion ventilation must be provided in storage areas containing flammable liquids. Provisions must also be made for manual or automatic roof venting. The use of roof vents will allow the smoke and heat to be vented so that firefighters can approach the fire;

(2) Flammable storage requires fire rated construction to segregate it from the rest of the warehouse. Separations of one hour fire resistive construction are required if the storage area is less than 150 square feet and two hours if more than 150 square feet. Storage quantities of up to 120 gallons are allowed for Class I-A, I-B, and I-C flammable liquids. These amounts may be increased by 100 percent (240 gallons) when approved storage cabinets are supplied and used. Automatic fire sprinkler protection and automatic fire alarm detection must also be installed in building at this quantity. Spill control is required when the aggregate quantity exceeds 660 gallons or individual storage vessels have 55-gallon capacities. Other requirements may be applicable by NFPA Code 30 or Overseas Buildings Operations (OBO) Architectural Engineering Design Guidelines. Consult OBO’s Design and Engineering Division (OBO/PE/DE) and OBO Fire Protection Engineering Division (OBO/OPS/FIRE/FPE) for specifics; and

(3) The Department reminds all employees of the importance of proper and secure storage for fire accelerants (combustible and flammable materials) and such weapons of opportunity. To ensure the safety and security of property and personnel, all materials that can be used as weapons of opportunity including, but not limited to, flammable or combustible liquids, must be stored as securely as possible when not in use to prevent access by unauthorized persons.

f. Climate-controlled room: In high temperature, or high humidity conditions, conventional storage facilities do not afford adequate protection to certain types of property against damage and deterioration. This is particularly applicable where property remains in storage for extended periods of time. If such conditions exist, consideration should be given to a climate-controlled storage room. Depending on the size of the storage space and the severity of the problem, the use of a window air conditioner might be adequate. In other areas the problem may require an additional dehumidifying unit or a larger cooling system.

g. Charging area: Electric powered materials handling equipment are powered by industrial storage batteries that will require periodic charging. If such equipment is to be used, a charging area should be established. The charging area should be in an area where traffic (workers, equipment) is minimal but accessible to equipment that needs charging. The area and ventilation requirements must conform to the latest edition of NFPA 70, National Electric Code. Safety features of the charging area must include:

(1) An eyewash station in the area capable of providing at least 15 minutes of running water at 0.4 gallons per minute. A plumbed unit providing tempered water is recommended, if feasible. The accountable property officer (APO) must implement procedures to test and flush plumbed units weekly to preclude the accumulation of bacteria and debris. If eyewash tanks are used, include "Hydrosep," or equivalent water preservative, in the reservoir to help maintain water quality. Portable eyewash bottles are not adequate;

(2) Battery leads are kept off the floor with retractable cable units;

(3) Acid spill clean-up absorbent materials or acid neutralizers along with pH paper for testing in case of a spill or leak from a battery;

(4) Label chargers to match the circuit breaker they are connected to and ensure that the power source capacity matches that of the chargers; and

(5) Provide a face shield, protective gloves and an apron for protection against acid spills and splashes when adding battery fluid to battery cells.

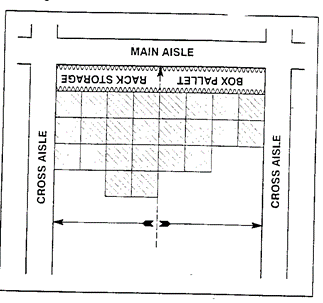

h. Aisles:

(1) The structure of the warehouse; quantity, nature, and activity of materials to be stored; and by the types and capacity of materials handling equipment available determines aisle layout. They should be planned with a view towards providing sufficient access to the property stored, loading and unloading facilities, fire protection equipment, and should be wide enough to provide maneuvering room for the materials handling equipment. They should be planned to provide straight and clear passageways unobstructed by support columns, elevators, heaters, or other such construction features;

(2) Normally, one or two main aisles run the length of the general-purpose warehouse. These aisles allow materials handling equipment or supplies to move straight through the length of the building. Typically, these main aisles are connected by cross aisles that are working aisles and allow material to be placed into and removed from storage. Aisles at least 2.39 meters (8 feet) wide are needed to help restrict the spread of fire across aisles (even when sprinklers are present) and to provide a means of egress and firefighting access. Aisle widths specified below for materials handling equipment are not to be construed as the absolute limitation for all operations. They represent the dimensions under which most operations may be conducted. The aisle widths specified are based upon a load of 40 inches:

(a) 2,000 pound trucks - 2.85 meters (9 feet 6 inches);

(b) 4,000 pound trucks - 3 meters (10 feet); and

(c) 6,000 pound trucks - 3.45 meters (11 feet 6 inches);

(3) Aisle widths for different load lengths will be determined on the basis that a variation of 20 centimeters (8 inches) in the load length will have a corresponding variation of 15 centimeters (6 inches) in the aisle width. For example, a 1.2 meter (4 feet/48 inches) load length will increase the aisle widths indicated above by 15 centimeters (6 inches);

(4) The recommended lift is a typical sit-down counter-balanced forklift which requires a minimum of 12 feet aisle widths. In cases where space is at a premium, stand-up reach lifts require a minimum of 9 foot aisle widths; and

(5) The width of aisles in bin and shelving areas should permit easy movement of stock selector trucks through the storage area. Generally, this requires an aisle of 75 to 90 centimeters (30 to 36 inches) in width.

i. Lighting must be sufficient to provide visibility during operations and must include emergency lighting features.

14 FAH-1 H-313.2 Storage Management

(CT:PPM-22; 03-03-2016)

(State/USAID)

During recent attacks on U.S. facilities, intruders used unsecured mission property as improvised weapons, i.e., weapons of opportunity. To ensure the safety of mission personnel and property, employees must properly secure and store all materials that can be used as improvised weapons, including, but not limited to, flammable liquids, paint, hand and power tools, rebar, rigid conduit, loose scaffolding, and other loose construction materials or equipment. Such materials must be stored as securely as possible when not in use to prevent access by unauthorized persons.

14 FAH-1 H-313.2-1 Storage Planning

(CT:PPM-50; 10-16-2024)

(State/USAID)

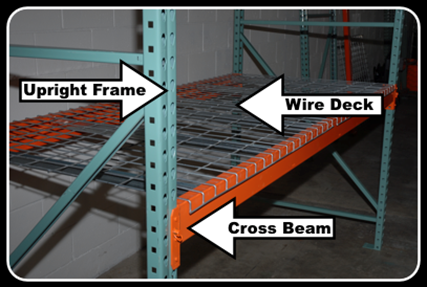

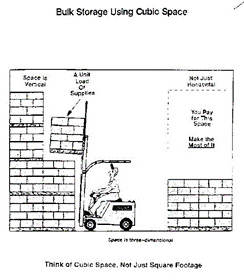

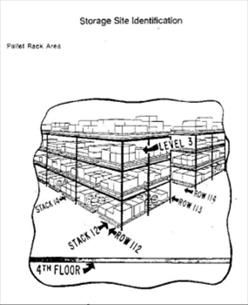

a. The prime objective of storage planning is maximizing available space. When practical, planning should provide for the full use of cubic footage, and items with similar handling requirements should be stored together. Heavier property should be placed on the lower shelves for stability and to minimize lifting hazards to employees. Grouping similar items facilitates storage and issue and contributes to effective care of supplies. Many bulky and heavy materials, which are difficult to handle, should be stored, when practicable, near doors, aisles leading directly to doors, or shipping/receiving areas where readily accessible with materials handling equipment and at the lowest level of storage racks to prevent accidents. The quantity of material on-hand also affects the amount of space required. It will frequently be desirable to increase the amount of space assigned to an item in a single location in order to eliminate the need for two locations. On small lots, other space savers, such as pallet racks and bins, should be utilized. Some property must be protected from dampness and extreme changes in temperature. Other property must be stored away from light and odors or protected from infestation of vermin and other pests. Property subject to pilferage requires special protection, and all property must be protected from fire. Storage of items must not interfere with automated fire suppression system and security video capabilities. Elevated earthquake threat zones have special engineering requirements for storage racks, and design loading and anchorage requirements should be developed using the latest version of the International Building Code, non-structural components sections.

b. Some property referred to as "shelf-life" items possess deteriorative or unstable characteristics to the degree that a storage time period must be assigned to ensure that they will perform satisfactorily when issued for use. Normally, shelf-life items are issued on a first-in, first-out basis. Additionally, some items contain heat sensor or other methods to visually notify staff that the temperature limits have been exceeded and therefore the item should not be issued for use. The accountable property officer (APO) must ensure that these items are properly identified in storage area locations and that first-in, first-out procedures are in place.

14 FAH-1 H-313.2-2 Bulk Supplies

(CT:PPM-22; 03-03-2016)

(State/USAID)

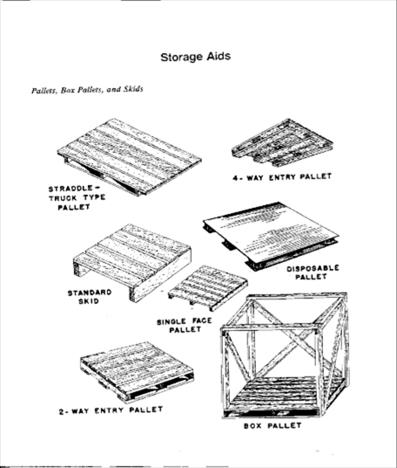

a. The storage of any large quantity of supplies, usually in original containers, is referred to as bulk storage. It is recommended that all bulk supplies be palletized using 1 meter x 1.2 meter (40 x 48 inches) pallets. Supplies should be uniformly arranged on pallets and, whenever possible, pallet loads should be uniform in quantity. To take advantage of cubic space, the pallets are stacked one on another. The height of the stacking depends on the crushability of the property, stability and safety of the stack, the maximum lifting height of the materials handling equipment, the floor load capacity of the storage areas, and the fire protection height limits.

b. Partially loaded pallets should be stored in pallet racks or on top of stacks. A full load should not be superimposed on a partial load, and a large load should not be superimposed on a small load. Heavy loads should not be stored on top of material that could be broken or damaged.

c. When the building is equipped with an automatic fire sprinkler system, the stack clearance below the sprinkler deflectors must be:

(1) At least 45 centimeters (18 inches) when stack heights do not exceed 4.5 meters (15 feet);

(2) At least 90 centimeters (3 feet/36 inches) when stack heights exceed 4.5 meters (15 feet); and

(3) At least 90 centimeters (3 feet/36 inches) when hazardous commodities are involved, regardless of stack height.

d. If the minimum water flow density is not achieved for rack storage, in-rack automatic fire sprinkler protection may be required.

e. The stack clearance below joists, rafters, and beams must be:

(1) 45 centimeters (18 inches) when stack heights do not exceed 4.5 meters (15 feet);

(2) 90 centimeters (3 feet/36 inches) when stack heights exceed 4.5 meters (15 feet); and

(3) 90 centimeters (3 feet/36 inches) in buildings without automatic fire sprinkler systems, regardless of stack height.

f. Around light or heating fixtures, a clearance of 45 centimeters (18 inches) must be maintained.

|

Example: pallet use |

|

|

14 FAH-1 H-313.2-3 Pallet Loading

(CT:PPM-22; 03-03-2016)

(State/USAID)

a. Durable recyclable plastic or other non-wood pallets are preferred for total lifecycle efficiency and environmental factors. Though they cost more, they last longer and wood-destroying organisms will not infest them.

b. The following loading practices should be followed because of the extreme importance of assuring stability of pallet loads:

(1) Use proper order: Place the inner containers of a layer first and then work out to the edges of the pallet;

(2) Distribute unused space: When loading containers which, because of their size or shape, do not completely cover the pallet's surface, the unused or vacant space should be distributed evenly throughout the pallet load;

(3) Distribute overhang: When containers or items overhang the pallet, they should be evenly distributed on the pallet;

(4) Cross-tie containers on pallets: Where possible, the containers should be cross-tied on the pallet in order to obtain maximum stability. Alternating the direction of containers on the pallet ties the containers together in a compact unit load. The method of cross-tying varies according to the size, shape, and crushability of the container; and

(5) Align the strongest edges of cartons: Most cartons have four edges, which are either reinforced, or more strongly constructed than the other four. For this reason the cartons should be placed with the strong edges positioned as vertical support for additional cartons and upper tier pallet loads.

14 FAH-1 H-313.2-4 Storing Bulk Supplies

(CT:PPM-22; 03-03-2016)

(State/USAID)

a. There are two basic methods of storing bulk supplies:

(1) Row stacking: The stacking of supplies from the wall or from any imaginary line to the aisle, leaving enough space between the stacks so that any row of pallet stacks can be withdrawn without interference. Other factors being equal, the layout of row stacks in an individual storage bay or area, bounded by two aisles, should be arranged so that the rows extend across the shortest dimension, since vacant space existing in a partially filled long row cannot be used for storage of other items until all the supplies stored in the row are completely exhausted. In large storage blocks surrounded by aisles, the stack should start at an imaginary or floor marked line running parallel to the longest dimension of the block. This arrangement provides for the storage, in back-to-back pallet rows, of different commodities and conserves aisle space as only one end of each row requires accessibility; and

|

Example: row stacking |

|

|

(2) Block stacking: Block stacking is the stacking of supplies in rows so that each row contacts another. In other words, there is no clearance or wasted space between the rows. Block stacking conserves space but should be used only when storing large quantities of an item. Extreme care should be exercised in block stacking to avoid interlocking pallets. Interlocked pallets create a hazard to operating personnel during stock withdrawal operations.

|

Example: block stacking |

|

|

b. Provided applicable local fire regulations do not stipulate a more stringent requirement, clearance between stacked, stored supplies, and exterior or interior brick or masonry, or other approved fire-resistant walls, need not be maintained for firefighting purposes:

(1) Except clearance for exceedingly large quantities of individual flammable or hazardous item lots must be 90 centimeters (3 feet/36 inches) between the wall and stored supplies; and

(2) At least 60 centimeters (2 feet/24 inches) clearance be must be maintained around interior fire doors.

c. Provided applicable local fire regulations do not stipulate a more stringent requirement, at least 60 centimeters (2 feet/24 inches) clearance must be maintained between any wood or other substandard exterior or interior wall and stacked, stored supplies

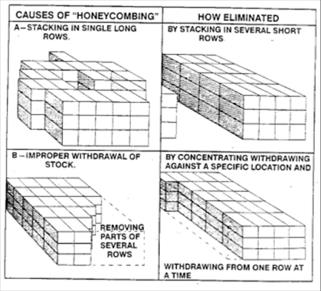

14 FAH-1 H-313.2-5 Honeycombing

(CT:PPM-22; 03-03-2016)

(State/USAID)

Honeycombing refers to storing and withdrawing supplies so that the empty space resulting from withdrawing is not usable for the storage of additional items. Material should be withdrawn row by row starting from the aisle and working back to the wall or imaginary line, and not across the whole front of the stacks. Withdrawals across the front of the stacks merely widen the aisle and do not create additional space for the storage of new commodities. Honeycombing also includes void spaces within the arrangement of materials on pallets, which results in space loss. When supplies are stored in more than one location in the warehouse, withdrawals should be concentrated against one specific location until stock is exhausted, thus creating space for new receipts.

|

Examples: honeycombing storage:

|

14 FAH-1 H-313.2-6 Small and Loose Issue

(CT:PPM-22; 03-03-2016)

(State/USAID)

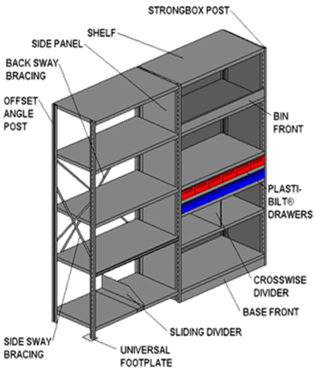

a. The use of various types of racks for storing small and loose issue supplies is an efficient means of obtaining maximum stock accessibility and cube space utilization. The use of pallet racks, for example, is particularly useful for the storage of large items of irregular shape not adaptable to pallet stacking.

b. Generally, small items (e.g., pencils, paper clips, staplers, staples, etc.) or items that are issued in less than standard package amounts (e.g., forms) require storage on open shelving, in shelving boxes, or in bins. Repetitive issue of small quantities of "binnable" type items from bulk storage can rarely be justified. Therefore, such items go into bins which minimize the inventory and security problems found where there are broken cases of binnable type items in bulk storage locations. When establishing a shelving/bin area, a somewhat central location is recommended with due regard to security, location of bulk storage, and shipping assembly areas. This will facilitate bin replenishment, reduce internal hauling, and lessen the work of consolidating bin items processed for issue with bulk quantities. Fast moving binnable items must be assigned space adequate to minimize replenishment frequency, time, and effort.

14 FAH-1 H-313.2-7 Sensitive and Pilferable Items

(CT:PPM-22; 03-03-2016)

(State/USAID)

a. A controlled access area must be established for the protection of sensitive property (property which requires a high degree of protection and control, and property which is of a high value which could include items that have the potential of being used against us as weapons of opportunity) and pilferable property (property having a ready resale value or personal appeal). Depending on the type and quantity of property to be protected, the area may be a lockable steel cabinet, or lockable room, wire cage, or vault. The area should be located in heavily trafficked locations most easily observed by staff and security personnel. A list of authorized personnel should be posted by the entry.

b. The codes of combination built in locks or padlocks must be strictly controlled and issued to authorized personnel only. A record must be kept indicating who has each combination.

14 FAH-1 H-313.2-8 Climate Control Storage

(CT:PPM-22; 03-03-2016)

(State/USAID)

a. The storage life of many items may vary according to the geographical location of a warehouse, and storage temperature and humidity conditions. Pressure sensitive tapes are considered semi-perishable items, heat being the most damaging factor. In general, the lower the storage temperature condition, the longer the life of the tape. Ideal temperature conditions are 18 to 24 degrees Celsius (65 to 75 degrees Fahrenheit). As the temperature rises above 24 degrees Celsius (75 degrees Fahrenheit), the life of the tape will be correspondingly shortened. Although relative humidity is not too important with respect to paper backed tapes, it is extremely important to the cellophane backed tapes.

b. The deterioration of many fabric items, subsistence, and leather stocks is accelerated when temperature exceeds 21 degrees Celsius (70 degrees Fahrenheit) and relative humidity is greater than 40 per cent. High temperatures also may cause certain plastics and similar materials to flow and change shape.

c. Posts in high-temperature, high-humidity locations should consider storing items such as transparent tape, rubber bands, machine ribbons, and other items that may be damaged by these conditions, in a climate-controlled room.

d. The control of humidity within storage structures is a method of protection, not a method of rejuvenation. Controlled humidity storage will not remove rust that is already present, nor will it restore material that has deteriorated prior to storage. Material placed in this type of storage in a condition other than clean may continue to deteriorate, particularly when contamination is of a corrosive nature.

e. Climate control also needs to be considered to protect employees from exposure to extreme temperatures. Warehouses in cold climates are usually heated. In climates where hot weather is the norm, air conditioning for employee health and safety is often not provided. In those cases, supervisors need to schedule work so that employees do not experience heat stress or exhaustion. Techniques such as scheduling heavy material handling tasks during cooler times of the day, frequent rest breaks, and working in teams should be employed.